Comprehensive Guide to Product Sourcing Criteria for Businesses:

Sourcing the right products is the core of good business in today’s competitive environment, the success of enterprises largely hinges on their sourcing strategies. The decision, making chain of brands that are well, established as well as small businesses and e, commerce startups goes through the gate of finding reliable suppliers, evaluating them, and engaging them. The art of product sourcing goes beyond the mere acquisition of items at the lowest cost, it is about creating partnerships that last, delivering uniform quality, and keeping up with the morals of your brand as well as its vision. Here are essential product sourcing factors that any company must consider while choosing and managing suppliers.

1. Product Quality and Consistency:

In fact, a product’s quality is what furnishes the basis for all sourcing decisions. Qualities most of the time serve as the promoters of a company’s good name, which leads to the brand’s increased return rates and customer loyalty being reinforced. When gauging product quality, think about:

Materials and finishing:

A product should be up to your technical and aesthetic requirements, at least.

Testing the performance:

Sampling is a must for testing the item’s features, its strength, and even its look before making a commitment to a large order.

Product certifications:

Go for ISO, CE, FDA, or any other certification as proof of compliance with the industry standards. Uniformity: A supplier should be able to assure you of the quality level in every single batch.

2. Pricing and Cost Efficiency:

Low prices may seem attractive initially, but the cheapest option is not necessarily the best one over time. Companies should focus on total cost of ownership rather than just the unit cost.

Consider:

- Base cost: the initial price per unit.

- Hidden costs: shipping, import duties, packaging, and warehousing costs.

- Payment terms: Look for flexible terms such as partial prepayment or net, 30/60 arrangements that facilitate cash flow

- .Volume discounts: Suppliers will be more willing to offer lower prices for larger quantities so be good in your negotiations.

- Currency fluctuations: If the sourcing is international, understand how changes in exchange rates can affect your total cost.A well, balanced pricing policy enables you to get the best value for your money while keeping the product quality and the ethical standards intact.

3. Supplier Reliability and Reputation:

- Track record: Find suppliers who have been around for a considerable time and have proven references.

- Financial stability: A supplier in good financial health will, therefore, be less prone to defaulting on orders or closing abruptly.

- Production capacity: Confirm that their current production volume is enough to satisfy your present and future demand to avoid delay.

- Communication: Honest communication that is straightforward, succinct, and upbeat reduces the possibility of misunderstandings and helps to build and preserve trust between parties.

- Internet reputation: Examine the endorsements, comments on social media,

4. Compliance and Ethical Standards:

Selecting partners that not only meet but exceed set standards is the way to ensure sustainable and long, term success. These factors will greatly contribute to the overall commitment to compliance that the company needs to have.

- Labor laws: It should be ensured there is: no child labor; no forced labor; safe working conditions.

- Environmental standards: It is necessary to pay attention to resource use, recycling, and energy, efficient production processes.

- Fair trade practices: Besides the fact that good wages are to be paid, workers rights should be respected.

- Regulatory compliance: Products will have to go through the necessary certifications and safety checks before they are allowed to be sold in your target markets.

- Ethical sourcing is crucial for brand integrity and also helps businesses to sustainable products.

5. Lead Time:

Lead time can be explained as the entire interval between when an order is placed and when it is received.

Production flexibility:

If the supplier’s demand were to change, would they be able to increase or decrease their production quickly?

Inventory management:

Are they stocking raw materials or are they relying on just, in, time manufacturing?

Shipping logistics:

Check web of shipping partners, methods, and delivery schedules reliability.

An accurate timetable is what a reliable supplier should offer and be able to prove that they can respond to the changes in the market.

6. Innovation and Technological Capability:

Innovation may provide a substantial competitive advantage in rapidly changing markets. Suppliers who employ state, of, the, art technology and maintain a commitment to continuous improvement may be the source of your business’s progress and success. You may want to:

- Automation and efficiency tools: New machines and digital systems make it possible to achieve high speed and accuracy.

- Research and development (R&D): Suppliers who invent new products or different uses for existing materials can be your source of unique, market, leading products.

7. Relationship Building and Trust:

At the core of the most effective procurement partnerships lie mutual trust and respect. A robust collaboration with a supplier might, in fact, pave the way to obtaining more advantageous terms, securing priority production spaces, and gaining early access to new product lines.

Participate regularly in:

Onsite visits or online meetings.Open communication regarding objectives and expectations.Prompt payments and fair negotiations.Cooperation over time instead of one, off transactions.A reliable relationship with a supplier brings about a solid foundation, lessens the unpredictability, and thus, enables the shared success to grow further.

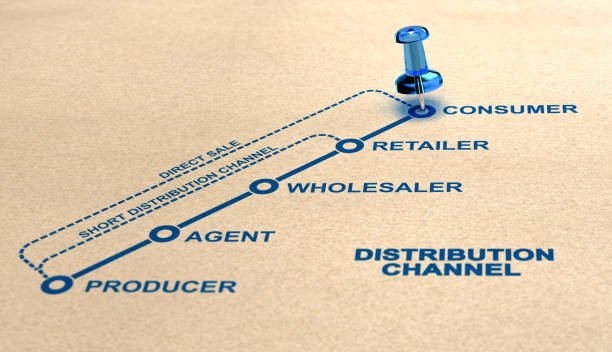

8. Location and Logistics:

- Sea freight is a money, saving method for large shipments.

- Air freight is faster but costly. Other charges may be customs duties, taxes, insurance, and FBA inbound fees.

- Warehousing and Fulfillment Amazon FBA is the solution for storage, packing, and fast delivery.

- Third, party logistics (3PL) is the way to go if you want more flexibility and cost control.

- Local storage is a good choice when you want to have direct inventory management.

- Supply Chain Risks Political instability can cause shutdowns of international trade. Natural disasters may cause shipment delays. T

- rade regulations and tariffs may lead to increased costs. By having multiple suppliers, you can reduce the risk of being dependent on one only. T

- echnology and Tracking, Real, time shipment tracking enhances visibility, Inventory management systems help to avoid stockouts, Logistics software improves coordination and efficiency.